Semiconductor tech: What exactly is India going to manufacture? Premium

The Hindu

Legacy semiconductor nodes are still in demand for certain applications, and India is wise to focus on them as it plans to begin its fabrication journey with nodes of 28 nm and higher.

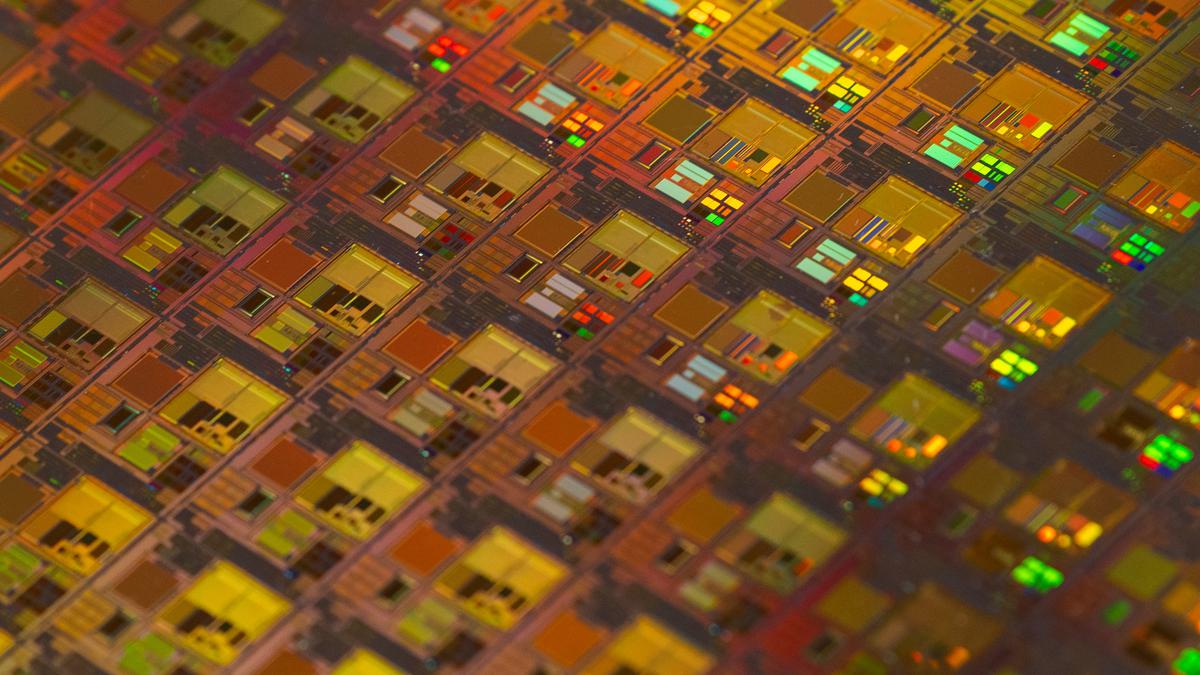

Sand plays a vital role in our daily lives. Used in its raw form, it is the foundation material for building homes. Purify the sand a little more and it becomes the foundation of the semiconductor industry.

India is currently waking up to its opportunities vis-à-vis semiconductors: access to the underlying technologies has been a long-standing dream of our nation. Success on this front would place India among a small, elite group of nations that have access to the tech as well as provide thousands of highly skilled jobs.

In a major setback, however, Foxconn Technology Group recently withdrew its support from its joint venture with Vedanta, Ltd. to establish a semiconductor manufacturing plant in Gujarat. The Indian government has also introduced incentives to catalyse this sector but only time will tell if they will bear fruit.

Initially, the plan was to establish a manufacturing unit for a 40-nm node. After Foxconn’s withdrawal, Vedanta has maintained that it acquired the relevant technologies from another major company. It is also in the process of acquiring the technologies for the 28-nm, 63-nm, and 90-nm nodes.

As a result, the term “semiconductor node” has become the talk of the town. What does it mean exactly?

What is a semiconductor chip?

At its core, a semiconductor chip is composed of transistors, which in turn are meticulously crafted from a specially selected material, typically silicon. One major function of a transistor is to encode information in the form of 0s and 1s, and to manipulate them to produce new information.

After Leader of the Opposition in the Assembly R. Ashok’s prediction on Saturday that Chief Minister Siddaramaiah will step down in November 2025 triggered intense political discussions in the State, Home Minister G. Parameshwara on Sunday said Mr. Siddaramaiah will continue for the full five-year term.

Run 3 Space | Play Space Running Game

Run 3 Space | Play Space Running Game

Traffic Jam 3D | Online Racing Game

Traffic Jam 3D | Online Racing Game

Duck Hunt | Play Old Classic Game

Duck Hunt | Play Old Classic Game