How are semiconductors fabricated? | Explained Premium

The Hindu

Semiconductors, the foundation of modern technology, shape our daily lives and hold the key to future innovations. This article explains how they are made.

While the physical realm of human activity contains an array of languages, the digital realm is founded on just one fundamental binary language: the 1s and 0s, also called the bits of data. Computers represent these bits as electrical signals and this forms the foundation of modern computing, communication, social media, robotics, and artificial intelligence. The 0s and 1s constantly shape the way we interact with technology and with each other on a daily basis – and the beating heart of this binary revolution is the semiconductor device.

Semiconductors represent a distinct class of materials that possess some of the electrical properties of both conductors and insulators. Like a faucet can be used to control the flow of water, semiconductors can be used to control the flow of electric currents, and with exquisite precision.

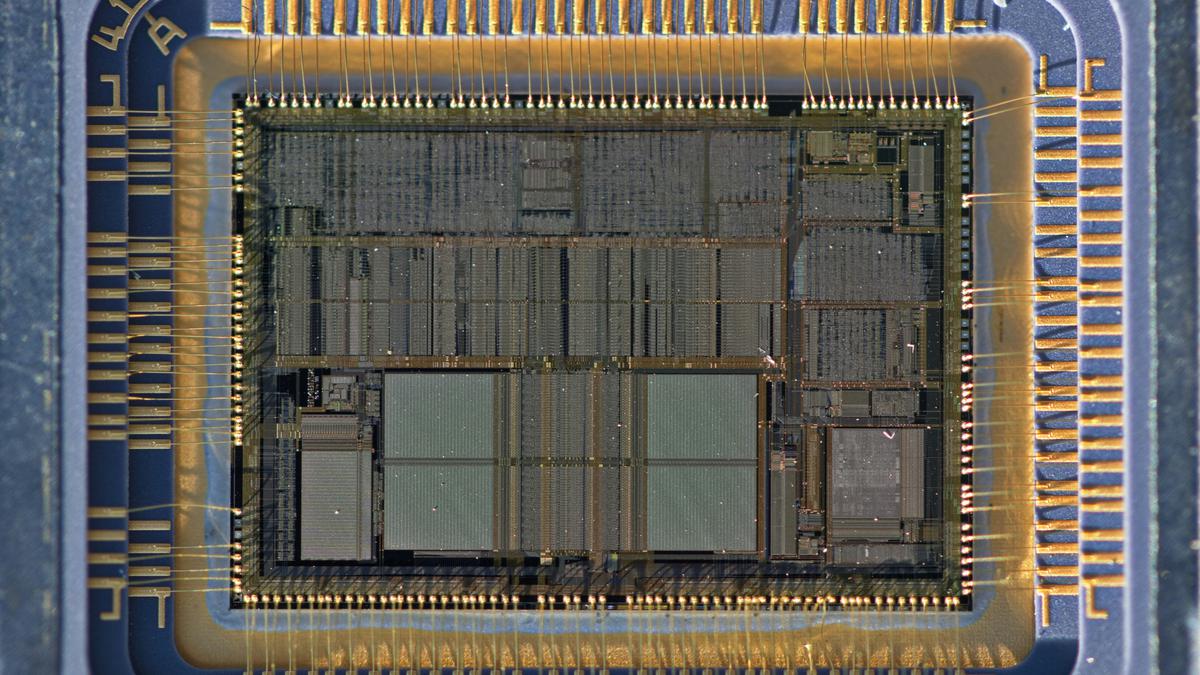

The most important type of a semiconductor is the transistor. At the dawn of the era of modern electronics, the first integrated circuits featured four transistors. Together, they controlled the flow of currents in such a way that the circuits could perform simple arithmetic operations. Today, we have single chips boasting billions of transistors.

Fitting so many transistors on a tiny chip no bigger than a fingernail requires extreme precision and a microscopic eye for detail. For instance, the accuracy required is equivalent to dividing a strand of human hair into a thousand segments each of specific width, and further subdividing each segment into a hundred parts. This is why fabricating semiconductors involves cutting-edge technology and science.

The process starts with an engineer carefully selecting a silicon wafer as the foundation on which the semiconductor will be built. A team puts silicon, sourced from sand, through a meticulous purification process to separate it from other substances, until they have an ultra-pure wafer with impurity levels as low as a few parts per billion. (This percentage is comparable to an error of merely 1 cm when measuring the earth’s diameter.)

Next is the photolithography process – a crucial step that carves the circuit pattern on the wafer. The wafer is coated with a light-sensitive material called a photoresist. Then, a mask is held in front of the wafer and light is shined on it. The mask contains small gaps in the shape of the circuit pattern. The light passes through these gaps and erodes the underlying parts of the photoresist. As a result, the photoresist on the wafer ‘acquires’ the pattern of the transistor circuits.

Following photolithography, engineers use chemical and/or physical techniques to remove the uncarved parts of the photoresist, leaving behind the circuit’s structure on the silicon substrate.

Run 3 Space | Play Space Running Game

Run 3 Space | Play Space Running Game Traffic Jam 3D | Online Racing Game

Traffic Jam 3D | Online Racing Game Duck Hunt | Play Old Classic Game

Duck Hunt | Play Old Classic Game