Sixth-generation aero-engine can be developed by tying up with foreign firm: DRDO chief

The Hindu

India must co-develop a sixth-generation aero-engine with a foreign manufacturer to enhance defense capabilities.

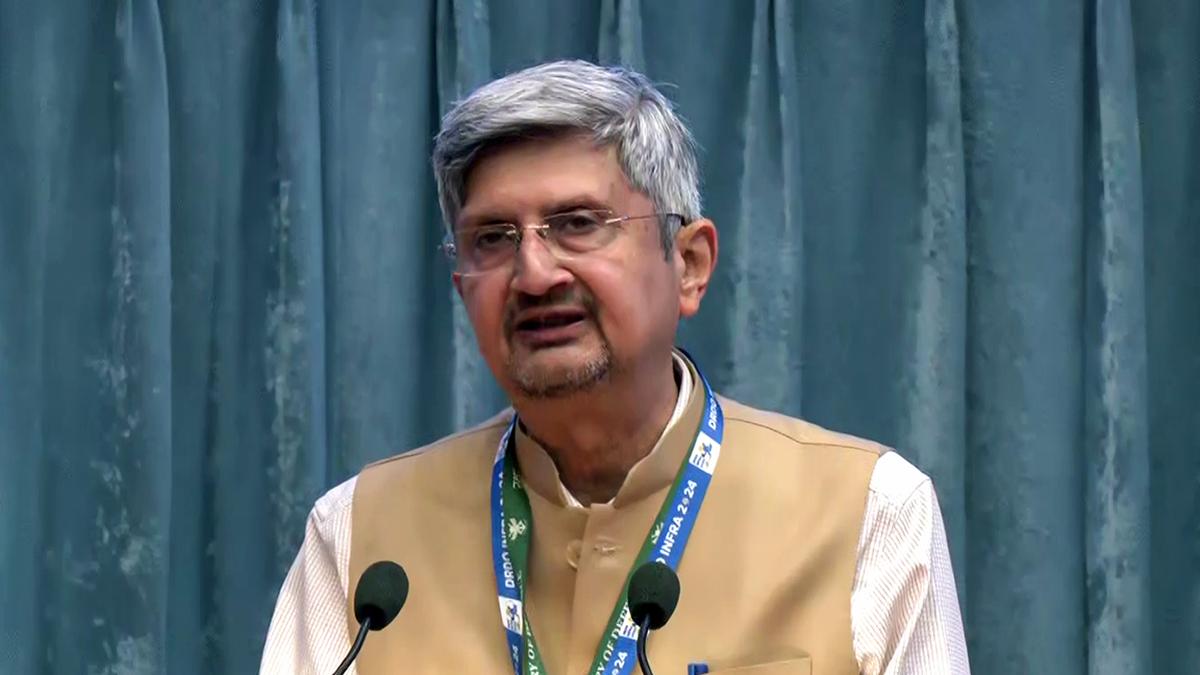

The only way India can develop a sixth-generation aero-engine and other technologies required is by co-development with a foreign manufacturer, Samir V. Kamat, Chairman of the Defence Research and Development Organisation (DRDO), said while noting that India currently invests only 5% of its defence budget for research and development, which needs to increased to 15%.

To realise that capability, he said the country will have to invest close to $4 billion to $5 billion, that’s ₹40,000 crore to 50,000 crore.

His remarks come against the backdrop of huge delays in the development of indigenous fighter jets, while China has made rapid progress in this area. Incidentally, India is in talks with France for the co-development of a 110KN engine for the fifth-generation jet, Advanced Medium Combat Aircraft (AMCA), that is on the drawing board and at least a decade away from the roll-out of a prototype.

There are still critical issues that need to be worked out before an agreement can be reached, sources said on the status of discussions between India and France.

The decision for the co-development of a new engine was announced during Prime Minister Narendra Modi’s visit to Paris in July 2023. Since then discussions have been going on between the DRDO’s Aeronautical Development Agency (ADA), Gas Turbine Research Establishment (GTRE), and Safran to work out the specifications and other modalities.

“If we look at what we need to do in terms of technologies, the first priority is aero-engines. Today, we have demonstrated a fourth-generation aero-engine for our fighter aircraft but going ahead we will need a sixth-generation aero-engine where the thrust to weight ratios exceed 10,” Mr. Kamat said, speaking at an event two days ago.

He detailed various technologies that need to be developed such as single-crystal blade powder metallurgy discs and ceramic matrix composites for static parts to begin with.

Run 3 Space | Play Space Running Game

Run 3 Space | Play Space Running Game Traffic Jam 3D | Online Racing Game

Traffic Jam 3D | Online Racing Game Duck Hunt | Play Old Classic Game

Duck Hunt | Play Old Classic Game