Researchers find alternative to cool supercomputers

The Hindu

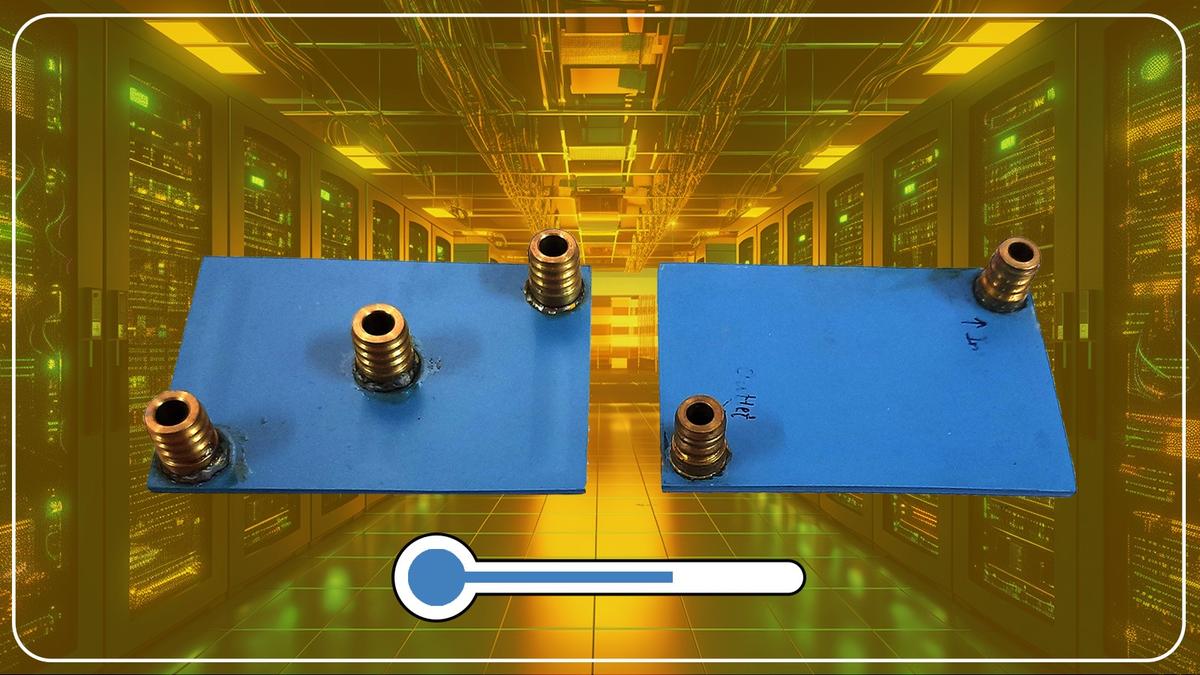

LTCC cold plates with microfluidic channels offer efficient cooling for high-performance computing systems, potentially replacing traditional copper cold plates.

Heat is an inevitable factor in the operation of any computing device, such as laptops, smartphones, or similar gadgets. The prolonged use in demanding tasks, such as gaming, often exacerbates this issue, leading to significant heat generation. Along with causing inconvenience to the user, this thermal buildup poses various risks to the device, ranging from performance degradation to potential hardware failures.

Every element within an electronic device, be it an integrated circuit, a resistor, or a capacitor, contributes to this thermal output, and necessitates maintaining an ideal operating temperature for optimal functionality. Exceeding this optimal temperature threshold jeopardises not only the individual components but also the overall device performance.

Larger and more complex systems, like High Performance Computing systems (HPCs) or supercomputers, resort to cooling using liquid coolants and cold plates that dissipate heat. In a recent study, a team of researchers from Indian Institute of Technology, Bombay (IIT Bombay) and Centre for Materials for Electronics Technology (C-MET), Pune have proposed using Low-Temperature Co-fired Ceramic (LTCC) as an efficient alternative to the conventionally used copper for making cold-plates.

In liquid cooled devices, liquid coolants like deionised water that is without any electrical charge, are circulated through the system to remove the excess heat. Cold plates are used like a heat sink transferring the heat from the circuit components into the coolant liquid. Copper is the preferred material for manufacturing cold plates, due to its low cost and high thermal conductivity. Parikshit Badhe, Senior project associate and a student at the Department of Mechanical Engineering at IIT Bombay explained, “Copper cold plates are extensively utilised for cooling in HPCs owing to their high thermal conductivity. However, there are limitations associated with copper, such as its weight, susceptibility to corrosion, and challenges in intricate design implementations.” Mr. Badhe worked under the guidance of Professor Shankar Krishnan and Professor Milind D. Atrey from IIT Bombay.

LTCC is a technology used to manufacture ceramic substrates for circuits. Substrates are materials on which electrical interconnections are printed and other components like resistors, inductors and capacitors are mounted. PCB (Printed circuit boards) is the most used substrate in our daily life electronic devices. LTCC Technology allows compact three-dimensional packing of the circuit, making them smaller and more efficient compared to conventional PCBs. “LTCC substrates are extensively used in electronic equipment expected to endure high temperatures, such as automotive and defence equipment,” Mr. Badhe said.

This new study demonstrates that microfluidic channels (micrometre sized tiny channels that allow flow of a liquid through it) can be created in an LTCC package to form a cold plate.

Thermal testing of these cold plates has shown that they can effectively cool microprocessor chips in supercomputers, successfully restricting temperatures below the safety limits, just as copper cold plates do. Professor Krishnan said, “This proof-of-concept demonstration is a breakthrough finding that paves the way for integrating cooling solutions directly into the chip package. Essentially, this research validates the concept that if a chip is made using LTCC technology, microfluidic channels can be incorporated into the same package, enabling localised cooling of hot regions by allowing the coolant to penetrate deep into the chip package.”

Run 3 Space | Play Space Running Game

Run 3 Space | Play Space Running Game Traffic Jam 3D | Online Racing Game

Traffic Jam 3D | Online Racing Game Duck Hunt | Play Old Classic Game

Duck Hunt | Play Old Classic Game