DATA | At current pace, Kavach implementation in Railways will take at least 50 years

The Hindu

Railway accident in Darjeeling highlights the need for India's ATP system 'Kavach' to prevent collisions, with slow progress.

The railway accident on June 17 involving the Sealdah-bound Kanchenjunga Express and a goods train in Darjeeling, West Bengal, has once brought focus to the absence of ‘Kavach’, India’s Automatic Train Protection (ATP) system. Ten people died in the incident. On average, 88 people are killed annually in train collisions in India (Chart 1).

Chart 1 | Number of people killed annually in train collisions in India.

Charts appear incomplete. Click to remove AMP mode

Railways Minister Ashwini Vaishnaw reviewed the progress of an advanced version of the ATP Kavach 4.0 a week after the accident. He directed the installation to be taken up in “mission mode”. Data show that availability of funds is not the worry for implementing Kavach; the issue lies with the pace at which it is being deployed.

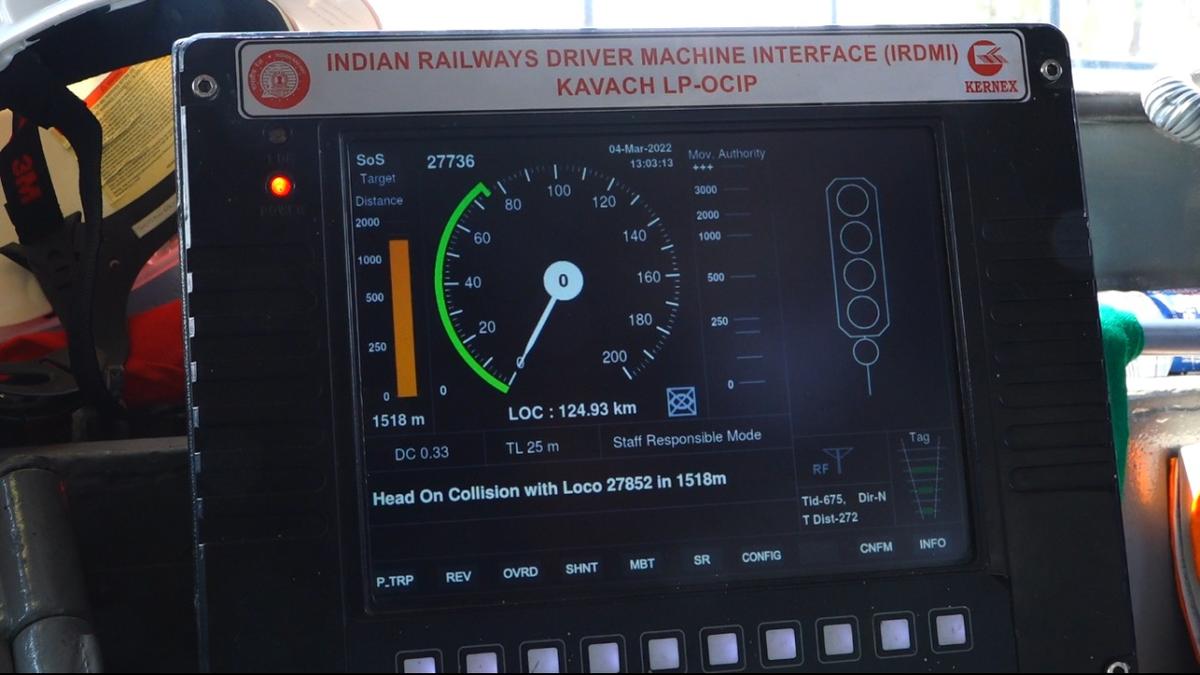

Also read: Explained | Understanding the Kavach system

Kavach can warn loco pilots if the train is at risk of overshooting the signal at red. It also has the capability of automatically applying the brakes if the loco pilot fails to reduce the speed below a certain limit. The three systems needed to implement Kavach are Radio Frequency Identification (RFID) tags placed in the tracks; the engine setup with RFID readers, a computer, and brake interface equipment; and radio towers installed at railway stations. The cost of installing Kavach in the tracks, including station equipment, is ₹50 lakh per kilometre. It costs ₹70 lakh to fit the equipment in one engine.

The route length of the Indian Railways is approximately 68,000 km. The cost of equipping Kavach on this route is about ₹34,000 crore (68,000 km X ₹50 lakh). There are about 15,200 diesel and electric engines in the Railways network. The cost of equipping the total fleet is ₹10,640 crore (15,200 engines X ₹70 lakh). In total, it costs about ₹45,000 crore to implement the system across all the tracks and in all the engines. Given that the job will require skilled labour, specially designed equipment, and traffic diversion during implementation, assuming a 10-year window for deployment would mean that the yearly cost would be ₹4,500 crore.

Run 3 Space | Play Space Running Game

Run 3 Space | Play Space Running Game Traffic Jam 3D | Online Racing Game

Traffic Jam 3D | Online Racing Game Duck Hunt | Play Old Classic Game

Duck Hunt | Play Old Classic Game